Exhaust

It’s not unheard of—even at this age—to find some vehicles still running on their original factory one-piece exhaust systems. While impressive, these systems are typically on borrowed time, and often fail at the welds connecting the pipes to the silencers, where cracks tend to develop due to age and vibration. Aftermarket exhaust replacements are widely available for petrol models, but diesel versions can be more difficult to source, especially when it comes to direct-fit systems.

Cars registered after 1st March 2001 must be fitted with a ‘Type-Approved’ catalytic converter, which meets stricter emissions regulations. Installing a non-type-approved cat on these vehicles will fail the MOT emissions test—something many buyers overlook when shopping for cheaper aftermarket parts.

A common sign of cat failure is the appearance of fault code P0420, which is triggered when the ECU performs an efficiency check—usually during steady driving at around 40 mph. This code indicates the catalytic converter is no longer effectively reducing emissions.

On diesel models, the converter can become clogged with soot, especially if the car is frequently driven on short trips at low speeds. A simple and effective solution is to take the car for a longer, higher-speed run, allowing the exhaust system to heat up and burn off carbon deposits. A few high-rev gear changes can often help clear the blockage.

Exhaust mountings are prone to cracking and breaking, especially if previously replaced with low-quality aftermarket parts, which tend to deteriorate prematurely. Another common weak point is the exhaust flexi-pipe, which often fails due to excessive movement caused by a worn rear gearbox mount allowing the engine to rock excessively. On the 1.4 and 1.6-litre engines, the flexi-pipe is integrated into the manifold downpipe section. When it fails, the simplest and most effective repair is to replace the entire manifold downpipe assembly. In contrast, on the Zetec 1.8 and 2.0-litre engines, the flexi-pipe is a separate component to the manifold.

Oxygen sensors are generally reliable, high-quality components that last a long time without issues. The main upstream sensor, located on the downpipe or converter itself, plays a critical role in managing fuel delivery and is often the first sensor owners consider replacing when faced with running problems. However, in most cases, the sensor itself isn’t actually at fault. While aftermarket oxygen sensors can perform adequately, they rarely match the accuracy of the originals in measuring the oxygen content in exhaust gases, which can affect engine performance and emissions. The rear (downstream) oxygen sensor is responsible for monitoring the efficiency of the catalytic converter. These sensors rarely cause problems unless they have been replaced with aftermarket units. Aftermarket sensors may fail more frequently, often due to issues with the heated elements inside the sensor.

Steering

The MK1 has rack and pinion power-assisted steering which is pleasantly weighted and delightfully precise, adding to that perfect driving dynamic. They can be pretty responsive with 2.9 turns lock-to-lock (in the ST170 and RS the rack is even quicker).

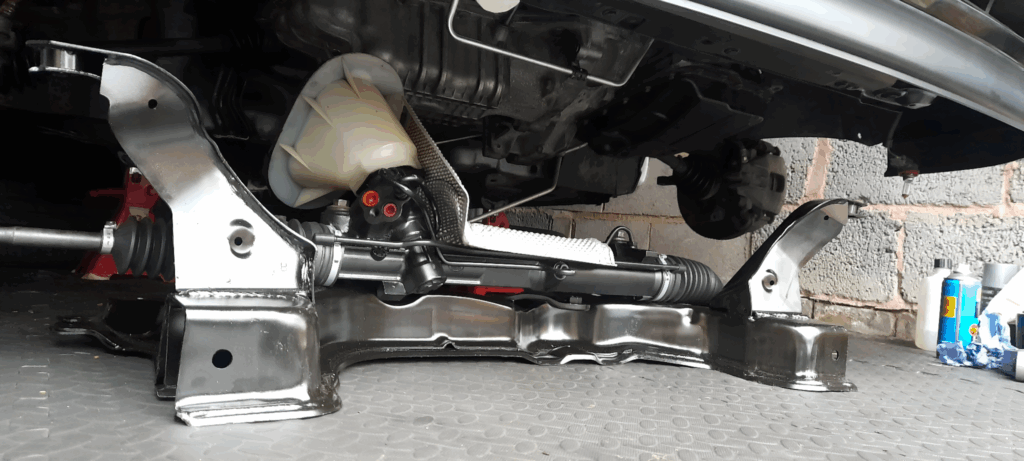

The steering racks can fail resulting in sudden tight spots when turning round a corner, this is caused by severely worn teeth in the rack. Replacement reconditioned or new aftermarket racks are decent quality for around £200-£450 but will require the front subframe to be dropped in order to fit.

Power steering pumps generally remain trouble-free as long as they don’t run dry. A common cause of fluid loss is the power steering switch bursting—a fault that should be addressed promptly if the switch hasn’t been replaced before. When the switch fails, the system can lose fluid rapidly, leading to loss of steering assistance and eventual pump damage. For long-term reliability, genuine replacement switches are strongly recommended.

On non-air-conditioned 1.4 and 1.6-litre models, keep an eye on the steel hard-line running across the front of the engine. These lines are prone to severe corrosion, and finding second-hand replacements can be challenging.

A complete power steering fluid flush is important for the longevity of both the pump and the steering rack. Early models originally used green hydraulic fluid, but from 2004 onwards, red ATF-based fluid was introduced. Despite this change, it’s highly recommended to switch back to the green hydraulic fluid when doing a flush, as it tends to provide better steering feedback and a lighter steering feel.

Suspension

The front suspension is a fairly conventional and compliant Macpherson Strut assembly with lower wishbones and anti-roll bar. The main achilles heel historically are the anti-roll bar drop links, which will start knocking very audibly from the cabin—MK1 suspension dynamics are very harsh on them and only high quality replacements will last more than a few years. The front springs have a wide profile which contributes massively to the comfortable ride and direct feel at the front, however they are prone to snapping at it’s bottom location on the strut. Shock absorbers are long-lived but gradually get lazy over time which is very noticeable once new ones have been fitted. If the wishbones are the originals they will be overdue a change, usually the ball joint will start knocking meaning a replacement arm is needed as the inner bushes will be perished causing poor wheel alignment.

Front subframes can corrode badly around the bottom wishbone mounting areas and aftermarket replacements are very reasonable around £90. Rear subframes are also subject to heavy corrosion after two decades of winters and aftermarket replacements can be sourced for around £230, however at the present you cannot get aftermarket estate rear subframes.

The ‘Control-Blade’ independent multi-link rear suspension is what makes a MK1 handle like a go-cart and mostly responsible for that class leading ride. Most of the components have lasted two decades with minimal issues but now they require a full-rebuild, the second most expensive hurdle in MK1 ownership!

As a serious safety concern make sure the rear suspension arms that support the springs are not heavily corroded, they can snap under pressure while driving which has led to reported incidents. Replacing the rear arms and springs is potentially an expensive job as all of the bolts will likely be seized in the arm bushes. This creates an expensive labour-intensive job when employing professionals, a rough figure is £400-600 to replace the rear arms, springs with new bolts!

The smaller rear control arms are generally strong and durable, but if you’re dealing with the original components, replacement is often necessary to restore proper function. One common issue is with the trailing arm bushes, which can separate from their metal collars over time. This separation leads to imprecise cornering and unpredictable handling — exactly the opposite of what makes the MK1 so special. Fortunately, these bushes can usually be replaced in situ, using the correct bush removal and installation tools. Renewing these components is crucial for regaining that signature stable, responsive, and confidence-inspiring ride.

Wheels & Brakes

The majority of models left the factory equipped with alloy wheels as standard, especially on mid-to-high spec models. A small portion came with steel wheels and plastic hubcaps, which were optional to upgrade at the time. Today, those original steel wheels with trims are increasingly rare, as many owners have swapped them out for alloys over the years. The wheel trims themselves are prone to becoming brittle and cracking, particularly after years of UV exposure or careless removal.

Most alloys are generally corrosive-resistant apart from ST170 alloys which corrode badly around the spokes . Optional accessory alloys are rarely seen on any examples today and generally aren’t particularly desirable due to some unorthodox designs at the time which never caught on. Ford also offered a range of optional dealer-fit alloy wheels, but these are rarely seen today. Many of these designs were stylistically bold for their time and never really caught on — making them more of a curiosity than a sought-after upgrade.

Most models were fitted with a front disc and rear drum braking setup. This configuration is generally reliable and low-maintenance, offering good braking performance for daily driving.

While the rear drums themselves are durable, they’re known for poor handbrake performance — a problem that usually stems from the self-adjusters failing to function properly. When the adjusters don’t keep the brake shoes tight against the drum surface, the handbrake travel increases and feels ineffective.

A common (and incorrect) fix is for owners to tighten the handbrake cable adjuster under the lever, which only stretches the cable over time and fails to address the root issue. Additionally, the rear wheel cylinders are a known failure point at this age if they’re still the original factory-fitted units, they will usually leak.

Original front calipers can partially seize in their bores and the seals can tear apart. At this moment in time replacing them with aftermarket ones is the most convenient solution and not too expensive.

Higher spec-models and most special editions of the Mk1 were equipped with rear disc brakes, typically in combination with ABS, and in some cases, traction control (which relies on the ABS sensor system for wheel slip detection). Wheel sensors are generally reliable and the ABS pump module is robust. The rear disc set-up gives consistent handbrake performance with little issues, hence why a drum-to-disc conversion has historically been popular.

Exterior & Interior Trim

Sourcing exterior trim for the Mk1 is generally quite manageable, with parts available through a mix of genuine new old stock (NOS), second-hand sources, and a steadily growing range of aftermarket replacements.

Many frequently replaced items — especially those prone to wear or cosmetic damage — are now available aftermarket at very reasonable prices. These include; front and lower grilles, bumper mouldings, fog light surrounds, indicator and light units. Most aftermarket trim pieces are affordable, with typical prices ranging from £10 for a fog light surround to £40 for a full set of bumper mouldings. Fit and finish can vary slightly between manufacturers, but overall quality is decent. Some parts are only available from Ford.

The biggest challenge when sourcing trim is for the less common body styles of the 3-door hatchback, Saloon and Estate. These variants often use unique exterior trim pieces which are not shared with the more common 5-door hatchback. As a result, certain parts are extremely difficult to find and rarely reproduced.

Interior trim is increasingly the difficult area for most models. If you have a 3-door hatchback, replacing damaged front door cards may prove difficult, because of their length they swell in the sunlight and may crack their window guides. The majority of the interior (excluding dashboard and centre console) is unique to the 3-door. The saloon and estate also. Getting good second hand trim when they come up is strongly advised. Some plastics can become scratched easily but overall pretty durable and have stood the test of 20 years at least.

Fabric seats are made from recycled materials and the seat pattern can wear very noticeably on some. Leather seats may need a re-dye at this point, a leather specialist can match the original colour using a swab sample so you can recondition the leather to a close OEM finish. The leather on post-2001 cars are less supple than earlier hides but no less durable — just a bit stiffer to the touch. The outer bolster on the driver’s seat can wear badly and even collapse, a repair is possible but may require a better seat slab from a breaker.

The steering wheel material on Mk1 varies by trim level, typically being either vinyl or leather-wrapped. Later wheels (especially on post-2001 facelift cars) often suffer from lower material quality, and are known to blister, peel, or degrade under prolonged sunlight exposure — a common issue, especially on higher-mileage or uncared-for examples. Early-model wheels (pre-2001) were of higher quality, particularly the leather versions, which were more supple, better-finished, and more resistant to wear.

Electrics

The electrical system is pretty organised, logical and simple for a car of its age. They give few issues even today, the main culprit is the tailgate wiring loom on hatchbacks. Commonly it breaks as it goes through into the tailgate. They are now fragile and with the opening and closing of the tailgate over many years which has eventually will break the wires. There are repair kits to solve this.

Engine bay earth locations can cause electrical gremlins but just need cleaning up, the two earth locations next to the battery are known for snapping in their threads. This can be due to washer fluid spilling from the reservoir filler neck and corroding them. You can find spare earth locations next to the battery on the inner wing.

Inside the cabin, the main weak spot on manual air conditioning models is usually the heater resistor pack. This component is located next to the fan motor and is known to fail, typically resulting in the heater only working on setting number four. The root cause is often water ingress, which enters through a leaky pollen filter seal or housing. When water gets in, it can cause the fan motor bearings to stiffen, putting extra load on the resistor pack and ultimately blowing it. This is arguably the most common historical fault on a MK1. To prevent it, it’s essential to replace the scuttle seal and reseal the bottom of the filter housing. Doing so will keep the footwell dry during rainfall and prevent the fan motor and resistor from being damaged.

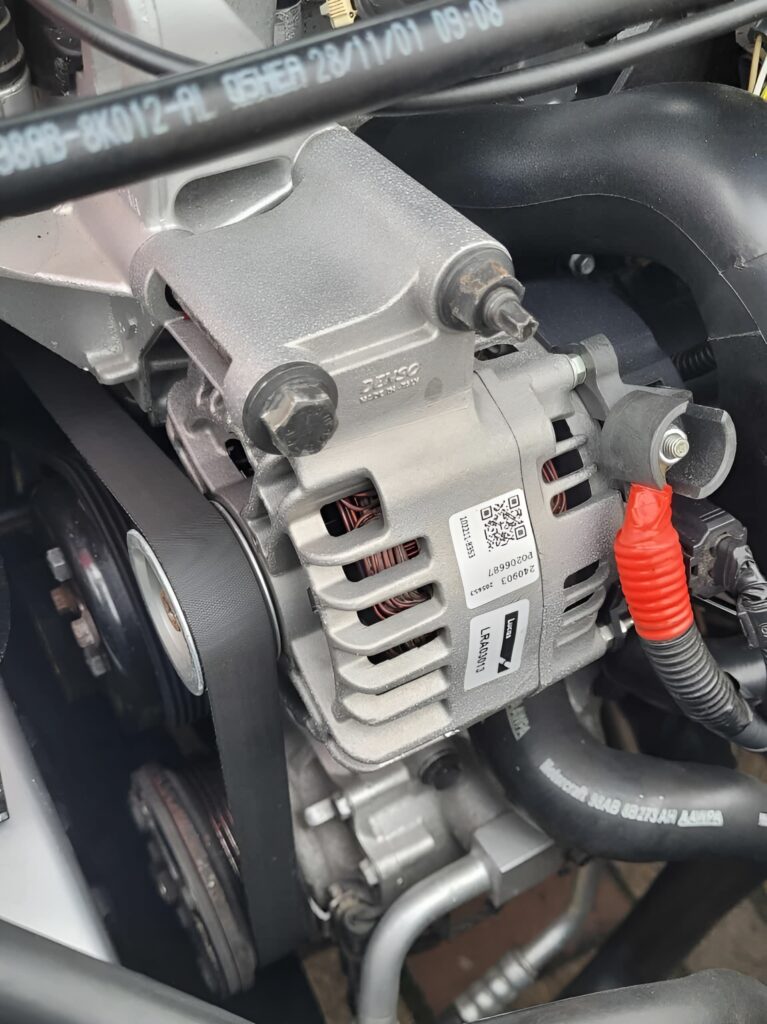

Alternators are generally very robust but can stop charging which is down to the voltage regulator brush pack wearing out or blowing. The advice is to replace the pack if the alternator bearing is smooth, otherwise a complete replacement is easily obtained. Starter motors are equally strong but can fail due to worn brushes or a failed solenoid, either way replacement brushes and solenoids can be obtained. Rebuilding them is strongly advised against inferior aftermarket types.

Occasionally owners have experienced the PATS immobiliser chip failing in the key fob, this is read by the PATS transponder ring (around the ignition barrel) which links to the PATS software in the ECU. Programming new keys is fairly simple in a MK1 and not something that forces you to approach an auto locksmith. By using Forscan software and the right laptop-to-OBD2 adaptor, you can programme new keys to the ECU (and erase keys).

On pre-facelift models, central locking is controlled by the CSM (Central Security Module) — a reliable unit with very few known issues. On facelift models, this system was replaced by the GEM (Generic Electronic Module), which is equally dependable. The remote key fob is programmed to either module to operate the central locking system.

Issues usually arise from dead batteries or batteries making poor contact with the fob circuit board. Central locking faults can be traced to poor and dirty connections in the harness connectors going into the front doors. Sometimes we get a faulty door actuator, these can become sluggish in cold weather due to hardened grease inside, leading to unresponsive locks. In some cases, they fail completely, causing a specific door to stop responding to the fob or interior locking buttons.

A common issue are intermittent faults with the speedometer cluster, often caused by poor factory soldering. While these clusters can usually be repaired professionally for around £80–£150, many owners in the past simply replaced them with second-hand units. Swapping in a used cluster means the displayed mileage may no longer be accurate. Always check the car’s mileage history online (e.g., via MOT history) before viewing or buying — this is a known issue and a potential red flag for mileage fraud or inconsistencies.

Another issue linked to the instrument cluster is the speedometer suddenly dropping to zero, often followed by the engine stalling. This is usually caused by a faulty gearbox speed sensor (can also be clock-related). On manual models, replacing this sensor isn’t overly technical, but it does require patience and care, especially when extracting the small retaining pin that holds the sensor in place — it can be stubborn and prone to snapping if rushed.